全球光伏产业开启了新一轮的景气周期,中国、日本和美国光伏市场的快速升温推动本轮景气周期,光伏技术的持续进步推动光伏市场的细分化程度不断升高,除地面电站、分布式等传统光伏发电的应用类型外,光伏技术和民用产品的结合应用开始展现生机。本文就光伏组件以EVA和PVB两种原料特性对比分析,探析其工艺特点。

The global photovoltaic industry has opened a new round of business cycle. The rapid warming of photovoltaic markets in China, Japan and the United States has promoted this round of business cycle. The continuous progress of photovoltaic technology has promoted the increasing degree of differentiation of photovoltaic market. In addition to the application types of traditional photovoltaic power generation such as ground power station and distributed power generation, the combined application of photovoltaic technology and civil products has begun to show vitality. This paper compares and analyzes the characteristics of EVA and PVB raw materials for photovoltaic modules, and analyzes their process characteristics.

EVA 胶膜在太阳能电池封装领域显优势

晶体硅太阳电池行业用的封装粘接材料为胶粘剂。上世纪80年代前,国内外曾试过用液态硅树脂和聚乙烯醇缩丁醛树脂片(PVB),但因价格高、施工条件苛刻、物性不好而被淘汰。80年代起国外开始研制 EVA 胶膜,它是一种热熔粘接胶膜, 常温下无粘性而具抗粘连性, 经一定条件热压便发生熔融粘接与交联固化。其在太阳能电池封装与户外使用上均获得了相当满意的效果。

EVA adhesive film has obvious advantages in the field of solar cell packaging

The packaging bonding material used in crystalline silicon solar cell industry is adhesive. Before the 1980s, Liquid silicone resin and polyvinyl butyral resin tablets have been tried at home and abroad (PVB), but it was eliminated because of its high price, harsh construction conditions and poor physical properties. Since the 1980s, EVA adhesive film has been developed abroad. It is a hot-melt adhesive film, which is non sticky and anti adhesion at room temperature. After hot pressing under certain conditions, melting bonding and cross-linking curing occur. It has achieved quite satisfactory results in solar cell packaging and outdoor use.

EVA(Ethylene Vinyl Acetate:乙烯-醋酸乙烯共聚物)

EVA是一种热熔胶,即在常温下,EVA是固体,没有粘性,透光性差。当把 EVA加热到一定温度时,EVA会熔化粘结在与它接触的物体上。用于太阳电池封装的EVA是专门设计的热固性热熔胶,即在加热熔融的同时会发生交联反应。当温度较低时,交联反应发生的速度很缓慢,完成固化所需要的时间较长,反之需要的时间就比较短。因此要选择适宜的层压温度,使 EVA在熔融中获得流动性,同时发生固化反应。随着反应的进行,交联度增加,EVA失去流动性,起到封装的作用。

在不同温度下的表现为:熔融温度(70-80℃)。此时EVA受热融化,流动性好,是抽真空的最佳时间。在固化温度下,此时EVA所含交联剂产生自由基,EVA分子间发生交联,产生三维网状结构,流动性变差,粘度变高。这个温度适合对组件进行层压,使其结构更紧密,与玻璃、背板的粘结度更高。在大于固化温度,此时交联剂分解出气体,容易使组件产生气泡,同时EVA交联度下降,容易硫化变黄,产生收缩。

EVA (ethylene vinyl acetate copolymer)

EVA is a kind of hot-melt adhesive, that is, at room temperature, EVA is solid, has no viscosity and poor light transmittance. When EVA is heated to a certain temperature, EVA will melt and bond to the object in contact with it. EVA for solar cell packaging is a specially designed thermosetting hot melt adhesive, that is, cross-linking reaction will occur while heating and melting. When the temperature is low, the crosslinking reaction occurs slowly, and the time required to complete the curing is longer, on the contrary, the time required is shorter. Therefore, the appropriate lamination temperature should be selected to make EVA obtain fluidity in melting and cure reaction at the same time. With the progress of the reaction, the crosslinking degree increases, EVA loses its fluidity and plays the role of encapsulation.

The performance at different temperatures is as follows: melting temperature (70-80 ℃). At this time, EVA is heated and melted with good fluidity, which is the best time for vacuum pumping. At the curing temperature, the crosslinking agent contained in EVA generates free radicals, and EVA molecules are crosslinked, resulting in three-dimensional network structure, poor fluidity and high viscosity. This temperature is suitable for laminating components to make their structure more compact and have higher adhesion with glass and back plate. When it is higher than the curing temperature, the crosslinking agent decomposes into gas, which is easy to cause bubbles in the components. At the same time, the crosslinking degree of EVA decreases, which is easy to vulcanize and turn yellow, resulting in shrinkage.

PVB(Poly vinyl butyral:聚乙烯缩丁醛)

1935 年, 美国科学家发明了一种可以用三明治方式夹在两层普通玻璃之间的高分子材料—聚乙烯醇缩丁醛, 英文名称为POLYVINLBUTARAL, 简写为PVB。它是通过高分子聚乙烯醇和丁醛缩合反应形成的一种聚合物,在最终的聚合物中有近23% 重量比的乙烯醇基。这种聚乙烯醇缩丁醛加上一种专用的增塑剂(一般为三甘醇酯类)进行增塑,通过挤出机系统和精确的厚度控制形成的一种连续化的0. 38~1. 52mm 厚的胶片。

PVB (poly vinyl butyral)

In 1935, American scientists invented a polymer material polyvinyl butyral, which can be sandwiched between two layers of ordinary glass. Its English name is polyvinlbutaral, abbreviated as PVB. It is a polymer formed by the condensation reaction of high molecular polyvinyl alcohol and butyraldehyde. In the final polymer, there is nearly 23% vinyl alcohol group by weight. This polyvinyl butyral is plasticized with a special plasticizer (generally triethylene glycol esters) to form a continuous 0.5-mm-thick plastic film through extruder system and accurate thickness control 38~1. 52mm thick film.

PVB胶膜与EVA胶膜二者区别

Difference between PVB film and EVA film

1、应用领域

EVA主要用于晶硅电池的封装,少部分薄膜也有采用,主要起到保护电池以及将电池片与盖板玻璃紧密贴合的作用。目前市场使用的产品以Dupont的Tedlar最为知名,但也有不少其他国际大厂在生产各种产品,如3M等,国内亦有几家能够用于太阳能的生产商,如福斯特、斯威克、海优威等;金韦尔EVA低温太阳能封装胶膜生产线在光伏胶膜行业处于垄断地位。

PVB目前主要用在薄膜电池、双玻组件、建筑一体化(BIPV)等领域,生产企业和产品型号均较少,目前以Dupont、Kuraray等为主,国内也有个别企业正在尝试生产,如鑫富药业等。

1. Application field

EVA is mainly used for the packaging of crystalline silicon battery, and a few thin films are also used. It mainly plays the role of protecting the battery and closely fitting the battery sheet with the cover glass. At present, the products used in the market are most famous in DuPont Tedlar, but many other large international manufacturers are producing various products, such as 3M, etc. there are also several domestic manufacturers that can be used for solar energy, such as foster, Swick, haiyouwei, etc; Jinweier EVA low temperature solar packaging adhesive film production line is in a monopoly position in the photovoltaic adhesive film industry.

At present, PVB is mainly used in thin-film batteries, double glass modules, building integration (BIPV) and other fields. There are few production enterprises and product models. At present, it is mainly DuPont and Kuraray, and some domestic enterprises are trying to produce, such as Xinfu pharmaceutical.

2、层压工艺

PVB、EVA对温度的要求不一样。EVA热塑性好,对设备要求没有PVB高。PVB对温度的要求较高(155℃左右),对层压机的要求比较高。

2. Lamination process

PVB and Eva have different requirements for temperature. EVA has good thermoplastic, and its requirements for equipment are not as high as PVB. PVB has higher requirements for temperature (about 155 ℃) and higher requirements for laminator.

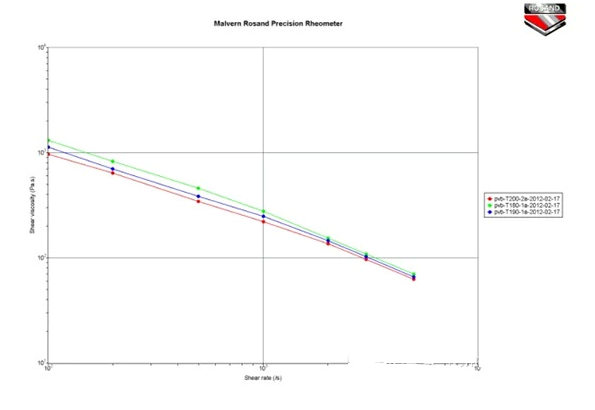

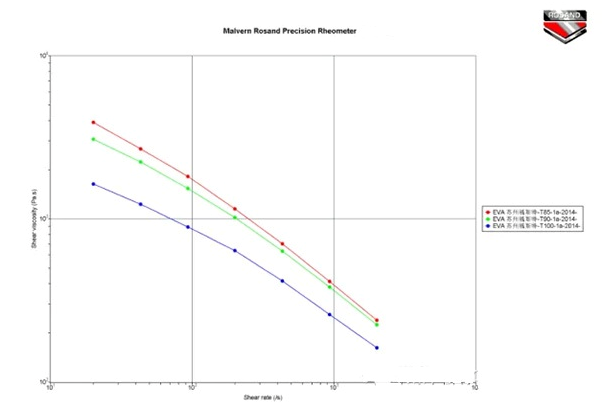

图注:PVB和EVA原料剪切速率-剪切粘度关系曲线对比

Note: comparison of shear rate shear viscosity curves of PVB and EVA raw materials

3、其他

PVB是建筑材料,对气体阻隔性能非常好,而且粘结性能很好,耐候性好很多。缺点在于对水汽的阻隔性能太差,这对太阳能电池而言是不可接受的。而且过于柔软不好操作。价格也是EVA的3倍以上。

3. Other

PVB is a building material, which has very good gas barrier performance, good bonding performance and good weather resistance. The disadvantage is that the water vapor barrier performance is too poor, which is unacceptable for solar cells. And it is too soft to operate. The price is more than three times that of EVA.

金韦尔机械全力支持您的产品开发,EVA与PVB都是热熔性胶膜,都是成熟的产品,各有其优缺点,应用在不同的领域。晶体硅太阳能组件的封装的潮流是使用EVA,其性能优良,价格实惠,是众多组件厂商青睐的产品;PVB非常适合用作在双玻组件和薄膜电池组件以及建筑一体化等领域,在这些领域,PVB的地位是无法替代的。针对不同原料的特性,我们一直从创新的源头,产品设计开始,通过吸收国外的前沿技术,对塑料原材料的特性分析解读,设计出最符合实际需求的PVB和EVA胶膜生产线。尤其是针对新材料的开发,提供定制化的解决方案,帮助客户实现最短流程的产品升级和转化。

金韦尔机械有限公司EVA胶膜生产线和PVB胶膜生产线系列设备以其稳定高效快速的自动系统装置,独特设计和处理工艺,精准把控产品膜厚度、热收缩率,保障硅晶片及组件的耐久性,光电转换效率提升。主要机型为3000mm EVA太阳能胶膜生产线 / 4000mm PVB胶膜生产线。

Gwell machinery fully supports your product development. EVA and PVB are both hot-melt adhesive films and mature products with their own advantages and disadvantages, which are applied in different fields. The packaging trend of crystalline silicon solar modules is to use EVA, which has excellent performance and affordable price, and is favored by many module manufacturers; PVB is very suitable to be used in the fields of double glass module, thin film battery module and architectural integration. In these fields, the position of PVB can not be replaced. According to the characteristics of different raw materials, we have been starting from the source of innovation and product design. By absorbing foreign cutting-edge technologies and analyzing and interpreting the characteristics of plastic raw materials, we have designed PVB and EVA film production lines that best meet the actual needs. Especially for the development of new materials, provide customized solutions to help customers achieve the shortest process of product upgrading and transformation.