PVB SGP Film Extrusion Line

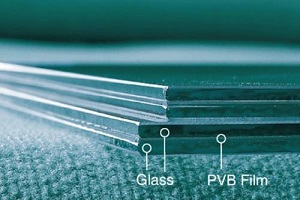

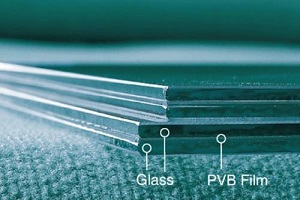

PVB film is a semi-transparent film with good adhesion to inorganic glass, and it is transparent, heat-resistant, cold-resistant and has high mechanical strength. PVB film can absorb the impact energy, and it do not produce broken pieces. This kind of safety glass is widely used in cars, high-rise buildings, bank counters, a variety of bulletproof glass. In the safety performance, it has excellent sound insulation, light control, heat preservation, heat insulation, shock resistance and other performance, so it is the world's ideal safe glass processing materials.

Main USES of PVB film extrusion line

1. PVB automobile safety glass film production line: PVB film is mainly used as the intermediate layer of automobile front windshield

2. PVB building glass intermediate film production line: PVB film is mainly used as the intermediate layer of high-rise building glass

3. PVB solar film production line: PVB film is used for packaging solar film batteries

Introduction of PVB Glass film production machine

China Gwell machinery CO. LTD. 's PVB film production line is a reliable brand. China's top three PVB manufacturers are using Gwell's PVB dry process (by roller) and PVB wet process (by water) film equipment. India's first PVB film production line is also made by Gwell.PVB film width: 3600mm(Max),PVB film thickness: 0.38-1.52mm,output: 500-800kg/h,shrinkage: ≤2%,total length of production line: 28m.It can be cut into desired width according to user's requirements.

Features of PVB Glass film production machine

1. Adapt to different types of processing systems with various material

2. From loading material to the final winding, it is using automatic mixing, PLC full integration, and it can do turnkey project

3. High output, low energy consumption and high degree of automation.

PVB film production line is divided into two kinds. One is a dry process, also called roll method of the process, through the stretch film extrusion, cooling stereotypes winding in the air. The other is a wet process, also called water craft, stretch film extrusion of film through tank cooling stereotypes, blow dry after winding. There are a lot of equipment differences between two kinds of process , and their prices is also very different. The main machine can adopt single screw extruder or parallel twin screw extruder according to different needs and raw materials. Please consult the sales engineer for details. PVB glass film production line is the core technology of Gwell.

SGP hot melt adhesive film production line product introduction

Gwell has developed a new generation of safety glass laminated film (SGP) film production line based on its own processing experience in plastic extrusion sheet equipment and integrated PVB film equipment.

SGP Film Main process

After accurately measuring and uniformly mixing the SGP raw materials and additives, they are plasticized and extruded by an extruder, and then the finished product is obtained by casting, cooling, and traction.

GWELL Equipment advantages:

(1) Fully automatic weighing type metering device to ensure high-precision feeding of various solid and liquid additives and raw materials. SGP is an ionic intermediate layer, which is composed of ethylene-methacrylic acid copolymer and a small amount of metal salt.

(2) The low-temperature extrusion system ensures good film performance while ensuring full mixing and plasticization.

(3) The special design of the casting part solves the problems of sticking roller and peeling.

(4) Unique online tempering and stress relief device.

(5) There are multiple tension control systems in the production line, so that the flexible sheet can be conveyed smoothly during the cooling, traction and winding process.

(6) The centralized control of Siemens PLC and industrial computer can easily realize closed-loop control.

Features of SGP film

(1) Compared with PVB film, it is stronger and more transparent. It is a good configuration for ultra-white glass.

(2) The tear strength of the SGP laminated glass interlayer film is five times that of ordinary PVB, and the hardness is one hundred times that of PVB. It is a good material for bulletproof glass.

The application of laminated glass produced by SGP

bulletproof glass, explosion-proof glass; mainly used in money transport vehicles, prisons, banks, glass open-air ceilings, glass stairs (it can adhere to metal well), handrails.

PVB、SGP Film Extrusion Line| Type | Single screw GWS150 | Single screw GWS150 / GWS90 | Twin screw GWP95 / GWP65 |

| Product structure | A | A,A / B,A / B / A | A,A / B,A / B / A |

| Production width | 2800mm | 2800mm | 3600mm |

| Production thickness | 0.38mm - 1.52mm | 0.38mm - 1.52mm | 0.38mm - 1.52mm |

| Output | 400KG/H | 550KG/H | 650KG/H |