作为一家专业的挤出机制造商,苏州金韦尔机械有限公司(以下简称:金韦尔)今年可谓捷报连连,成果累累,公司一口气推出了PET合金板生产线、TPU薄膜挤出生产线、PMMA特种导光板生产线和PP/PA魔术贴生产线、高产量湿法pvb汽车膜生产线等多种新产品,广泛应用于光学片材、鞋材、成衣、充气玩具、水上及水下运动器材、医疗器材、健身器材等领域,市场反响强烈,发展势头迅猛。

As a professional extruder manufacturer, China Gwell Machinery Co., LTD (hereinafter referred to as: Gwell) this year can be said to be a series of good news, achievements, the company launched a PET alloy plate production line, TPU film extrusion line, PMMA special light guide plate production line and PP/PA Velcro production line, high yield wet PVB car film production line and other new products, Widely used in optical sheets, shoes, clothing, inflatable toys, water and underwater sports equipment, medical equipment, fitness equipment and other fields, the market response is strong, rapid development momentum.

Sun Fenglin (right), General Manager of Gwell

金韦尔总经理孙锋林高兴地说: “ 我们公司研发的PET合金生产线,与其说是一条挤出生产线,更恰当地说应该是一种新的成型工艺和配方工艺。该生产线采用了特制的双螺杆挤出机和抽真空工艺,能确保多种本不相容的材料无缝相容,物理和化学性能较传统的PET片材有很大的提高。它可以生产PET/PC、PET/PE、PET/PP等多种PET合金,配方适应性很广。另外,由于原料主要取自于回料,原料成本大幅降低,比如我门研发的一款PET/PE合金,综合性能超过ABS,但成本比ABS低了近三千元,利润空间非常可观。 ” PET合金挤出生产线很好地响应了国家提出的绿色工业的号召,每年我国有大量的PET回料无法充分利用,这导致污染加剧,原材料成本上涨,再加上国家对废旧塑料进口的限制,不少企业难以为继。而金韦尔PET合金板生产线片材的综合性能优异、性价比高,能够很好地实现回收再生产、再利用,不仅可以减少环境污染,而且大幅度降低了原料成本,增加利润,获得了国内多家大型国企的青睐。

EVA solar film, glass laminated film production line

据孙总介绍,他们的PET合金生产线是国内首批原型机,客户也刚刚完成验收,还要做大量的材料测试工作,但初步得到的数据还是很令人振奋的。 孙总认为PET合金生产线前景乐观,对于国家来说,这个项目是真正意义上的环保项目;对于客户来说,该生产线做出的产品性能优越、价格有竞争力。他预计,这一行业在2018年将获得长足的发展,非常值得期待。

According to Sun, their PET alloy production line is the first batch of prototype machines in China, the customer has just completed acceptance, and a lot of material testing work needs to be done, but the preliminary data is very exciting. Sun thinks that the PET alloy production line has an optimistic prospect. For the country, this project is a real environmental protection project. For customers, the product line is superior in performance and competitive in price. He expects the industry to see significant growth in 2018.

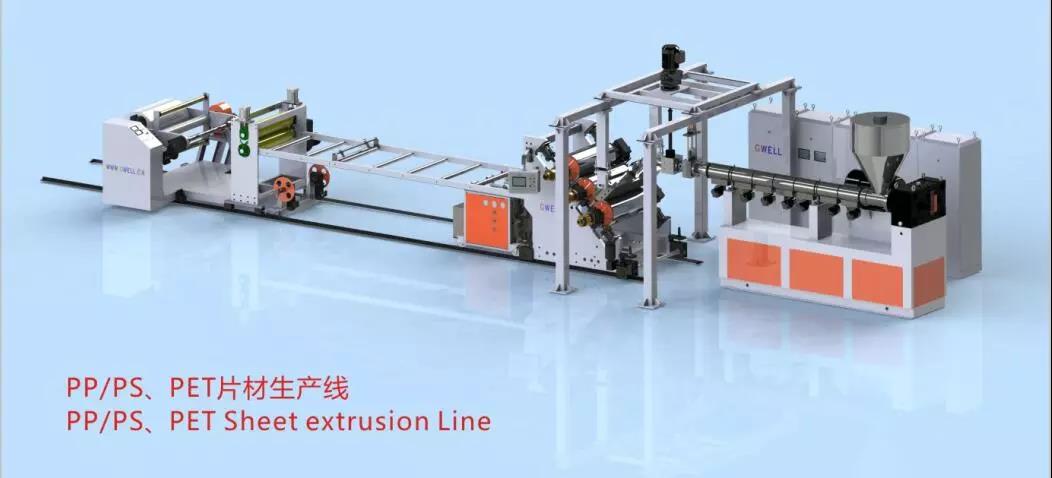

PP, PS, PET sheet extrusion line

随着国民品质意识的提高和消费者对高品质产品的肯定,越来越多的高端产品将逐步替代低端产品,很多新材料新技术将获得大规模使用。与此同时,挤出设备市场近年来发展迅速,各种新材料应用应接不暇,这就要求承接设备的企业有较强的研发能力和一站式交付的能力,而金韦尔公司恰好在这个方面有独特的优势,他们对未来开发的研发和生产十分有信心。 “ 对于公司未来的发展,我们一向坚持‘研发先行,市场牵引’的发展策略,随时迎接市场的挑战。我们目标是2018年,金韦尔销售额超1.5亿,再开发3-5项新品,进入2-3个新行业、新领域。 ” 孙总说。未来,金韦尔还会继续在新能源和新材料领域发力,不断提升公司产品品质、开拓新品市场,避免国内日益激烈的同质化价格竞争,走出金韦尔自己的独特发展道路。

With the improvement of national quality awareness and consumers' recognition of high-quality products, more and more high-end products will gradually replace low-end products, and many new materials and technologies will be used on a large scale. At the same time, the extrusion equipment market has developed rapidly in recent years, a variety of new material applications are overwhelmed, which requires enterprises to undertake equipment have strong research and development ability and one-stop delivery ability, and Gwell company just has a unique advantage in this aspect, they are very confident in the future development of research and development and production. "For the future development of the company, we always adhere to the 'r & D first, market traction' development strategy, ready to meet the challenges of the market. We aim to achieve sales of more than 150 million in 2018, develop 3-5 new products and enter 2-3 new industries and fields." The sun always said. In the future, Gwell will continue to make efforts in the field of new energy and new materials, constantly improve the quality of the company's products, develop new markets, avoid the increasingly fierce homogeneous price competition in China, and walk out of kingwell's own unique development path.