Gwell Manufactures The First PVB Film Production Line In India

Views:

Date:2016-12-30

苏州金韦尔机械有限公司是一家专注于EVA/PVB/TPU胶膜生产线的高新技术企业。公司在2017年9月初成功和印度客户签订PVB胶膜生产线,该线是印度国内第一条PVB胶膜设备,填补了印度玻璃夹胶膜行业的空白,标志着印度国家PVB工业的起步。设备经过金韦尔工作人员3个多月的努力,以及印度客户的支持,在我司工厂成功带料试机,做出客户满意的制品,得到客户的认可和支持。该生产线将有助于客户在印度迅速抢占市场,为后期的发展奠定良好的基础。

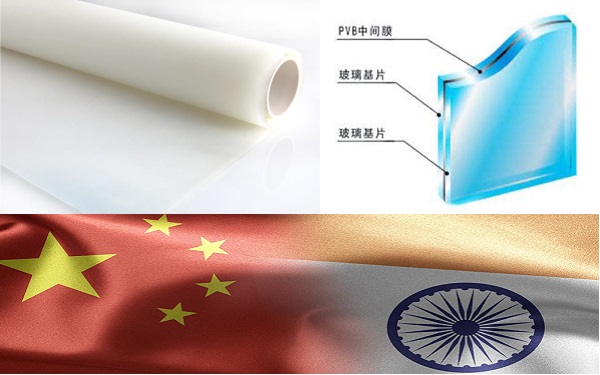

China Gwell Machinery Co., Ltd. is a high-tech enterprise focusing on EVA / PVB / TPU film production line. In early September 2017, the company successfully signed a PVB film production line with Indian customers. This line is the first PVB film equipment in India, filling the gap in India's glass laminated film industry and marking the start of India's national PVB industry. After more than 3 months of efforts by Gwell staff and the support of Indian customers, the equipment has been successfully tested with materials in our factory and made products satisfactory to customers, which has been recognized and supported by customers. The production line will help customers quickly seize the market in India and lay a good foundation for later development.

苏州金韦尔机械有限公司在2017年里承接多套PVB中间膜全套设备的订单,分别涉及干法、湿法工艺,中国前三位PVB玻璃夹胶膜制造商工厂都有金韦尔设备在服役。公司与国内知名高校合作,共同研发,再经过多次试验之后,已经掌握了PVB中间膜设备的干法、湿法的全套工艺技术,这一技术在国内处于优势地位。金韦尔设备目前产品宽幅到4000mm,可根据用户要求分切成所需宽度,厚度0.38-1.5mm,产量每小时900公斤,全套集成控制,可以做交钥匙工程

金韦尔公司能有现在的发展,离不开自身的不断努力,也离不开广大客户的信任和支持。公司近年来,在EVA胶膜、TPU胶膜、PVB胶膜等领域,设备均实现批量化生产,满足客户对市场的需求。金韦尔公司在发展的同时,也紧抓生产质量,保障每一条交出去的设备确认无误;同时金韦尔公司领导也加大与配套厂家的合作,生产线主要大的部件均采用国际知名品牌,如模具采用精诚或EDI的、电机采用西门子的、变频器是用瑞典ABB的、测厚仪主要用的是法国思肯德品牌的、计量泵采用玛格的等,从细节可以反应出公司对设备细节要求之高,且公司产品定位于中高端,对设备的安装制作过程中严格要求自己,保障每一条都能给客户创造最大价值。

欢迎广大客户来我们金韦尔苏州工厂和大丰工厂考察交流,期待与您的合作。

In 2017, China Gwell Machinery Co., Ltd. undertook orders for multiple sets of complete sets of PVB intermediate membrane equipment, involving dry process and wet process respectively. Gwell equipment is in service in the factories of the top three PVB glass laminated membrane manufacturers in China. The company cooperates with well-known domestic universities to jointly research and develop. After many tests, the company has mastered a full set of dry and wet process technology of PVB intermediate membrane equipment, which is in an advantageous position in China. At present, the product width of Gwell equipment is 4000mm, which can be divided into the required width according to the user's requirements. The thickness is 0.38-1.5mm, and the output is 900kg per hour. The full set of integrated control can be used as a turnkey project

The present development of Gwell company is inseparable from its own continuous efforts and the trust and support of its customers. In recent years, the company has realized mass production of equipment in the fields of EVA adhesive film, TPU adhesive film, PVB adhesive film and so on, so as to meet the market demand of customers. While developing, Gwell also pays close attention to the production quality to ensure that each delivered equipment is confirmed to be correct; At the same time, Gwell's leaders have also increased their cooperation with supporting manufacturers. The major components of the production line are international well-known brands, such as Jingcheng or EDI for molds, Siemens for motors, abb for frequency converters in Sweden, sikende brand in France for thickness gauges, and MAG for metering pumps. The details can reflect the company's high requirements for equipment details, Moreover, the company's products are positioned at the middle and high end, and strictly require itself in the process of equipment installation and production, so as to ensure that each can create maximum value for customers.

Welcome customers to visit our Gwell Suzhou factory and Dafeng factory, and look forward to your cooperation