PP、PE、PVC、PC、ABS Profile Extrusion Line

(PP、PE、PVC、PC、ABS Single Profile Extrusion Line)

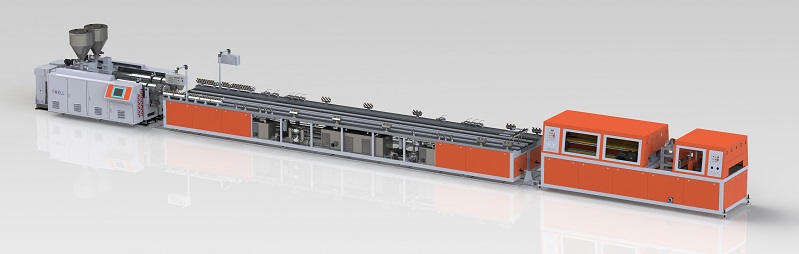

Gwell machinery of double profile extrusion production line has independently developed profile auxiliary machines for European and American markets. This model has been successfully sold to the United States, Turkey, Poland, Russia and other countries and regions. Compared with domestic ordinary profile auxiliary machines, this auxiliary machine has the characteristics of low energy consumption (energy saving of more than 21%), water saving (independent double circulation, special increase of water tank design), high efficiency, convenient operation (invention patent), humanization and so on.

(PP、PE、PVC、PC、ABS Double profile extrusion line)

PVC plastic steel profile and PVC, PE, PP wood plastic production line

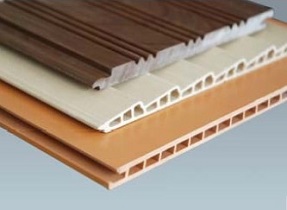

At present, there are two kinds of wood plastic extrusion production lines: one-step method is often used to produce PVC wood plastic products, and two-step method is used to produce PP / PE wood plastic products. The screw barrel adopts bimetallic treatment, with wear resistance and corrosion resistance, good mixing and plasticization, high output, energy saving and consumption reduction. It can adapt to wood flour or other plant fibers with a filling amount of up to 50-70%. The optimized screw design has small shear force and is not easy to cut wood fibers, which can make the materials stay in the machine for a uniform time. Single machine two-stage mixed direct extrusion of extruder, or two-step extrusion after granulation, which saves power and space. It has the characteristics of high output, stable extrusion pressure and good plasticizing and mixing effect.

The production line can produce PE, PP or PVC wood plastic profile products, which are mainly used for pallets, packing box boards, floors, outdoor decoration materials, etc. After adding or replacing different parts, it can be used to produce plastic steel profile, gusset plate, windowsill plate, wall hanging plate, wave plate, wood plastic floor, guardrail, door panel, door pocket, line and other building materials products. It is also an ideal choice for making WPC products such as wood plastic tray, indoor and outdoor floor, guardrail, plank, outdoor landscape materials and so on.

Company's product series: wood plastic one-step thick plate equipment; Wood plastic one-step profile equipment; Wood plastic one-step decorative profile equipment; Wood plastic granulation equipment; Various wood plastic molds.

(PVC plastic steel door and window profile production line, PC profile production line)

PVC, PP, PE, PC, ABS customized profile extrusion production line

The company has absorbed advanced technology at home and abroad and successfully developed a customized profile production line suitable for user needs. The unit is composed of single screw extruder or twin-screw extruder, vacuum setting table, tractor, cutting machine and turnover frame. The production line has the remarkable characteristics of good plasticization, high output and low energy consumption. The host adopts imported AC frequency converter for speed regulation, and the temperature control instrument adopts Japanese RKC or Fuji products. The auxiliary vacuum pump and traction motor are high-quality products with simple maintenance.

Profile extrusion line parameters (please consult the sales engineer for details)

| Extruder type | GWS series single screw extruder | GWC series Conical twin screw extruder | GWP series Parallel twin screw extruder |

| Extruder model | GWS65/28; GWS90/28; GWS120/28 | GWC65/132; GWC80/156; GWC92/188 | GWP75/44 ; GWP92/44 |

| Output | 120KG/H - 350KG/H | 180KG/H - 550KG/H | 300KG/H - 500KG/H |

| Auxiliary model | YF50、YF108、YF180、YF240、YF300、YF400、YF500、YF600(door plank)、YF800(door plank)、YF1000(door plank)、YF1250(door plank) | ||

| Product width | 50mm - 1250mm (The product width is determined by the auxiliary machine model) | ||