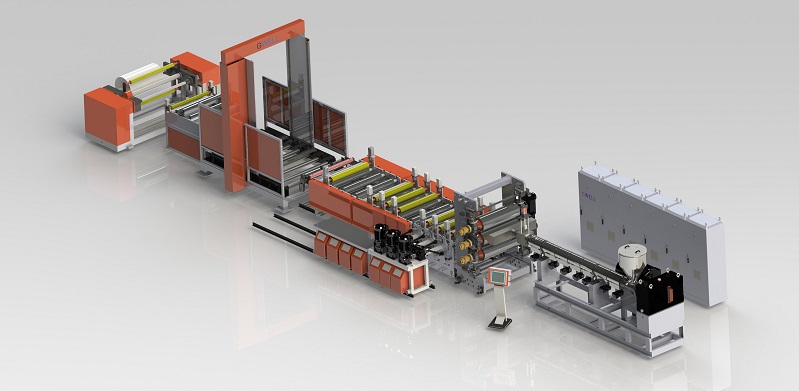

Stone Paper Machinery Direction Orientation (MDO) Extrusion Line

Views:

Date:2018-04-02

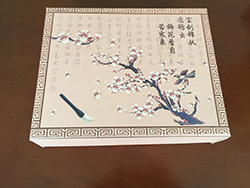

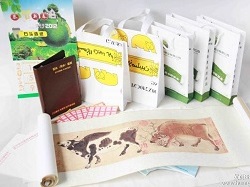

(Picture of the sixth generation Gwell Stone paper equipment,Uncoated)

1. Stone paper product introduction:

Stone paper is a kind of new material between paper and plastic, which can not only replace part of the traditional functional paper, professional paper, but also replace most of the traditional plastic packaging. With the characteristics of low cost and controllable degradation, it can save a lot of cost for users and will not produce pollution. From the point of view about replacing part of the traditional paper, it can save a lot of forest resources for the society and reduce the secondary pollution in the paper making process. From the perspective of replacing part of the traditional plastic packaging, it can save a lot of strategic resources of petroleum for the country (2.3 tons of petroleum can be saved when every 1 ton is used), and the product can degrade after using without causing secondary white pollution. Stone paper, a new environmental protection material, is a sunrise industry with strong vitality.

2. Product features:

Stone paper production process is simple; Large investment, high output and low energy consumption; Do not need to use plant fiber, do not need to cut down trees, and it can save a lot of wood and protect the natural ecology; Also it do not need to add strong acid, strong alkali, bleach and other chemical raw materials and will not discharge waste water, waste residue and toxic and harmful gas, so it belongs to the green environmental protection products. The product has good mechanical performance, waterproof, moisture-proof, moth-proofing, folding resistance, tear resistance, oil resistance, non-toxic, odorless, pollution-free, geometric size stability, high printing clarity. After discarded, it can be naturally degraded into powder to return to nature.

3. Product category:

Category I: degradable environmental protection packaging material series products. The product is mainly used to replace the traditional plastic packaging products; There are two main series of industrial packaging materials and life packaging materials, including industrial packaging materials: dust covers and protective covers of electronic, household appliances and industrial equipment products ; Life packaging materials including: daily use packaging bags, shopping bags, garbage bags and even roll bags and other products. This kind of product has very strong social value and market advantage.

The social value lies in:

1. The products have photodegradation, oxidative degradation and biodegradation properties. Further the use of stone paper can fundamentally solve the problem of "white pollution" which oppresses mother earth day by day.

2. As a large amount of calcium carbonate is used, each ton of environment-friendly packaging material can save 2.3 tons of petroleum resources for the country. The market advantage lies in that consumers not only bear the responsibility of social environmental protection, but also can save 15% ~ 30% of the use cost.

The second category: environmental protection stone wall paper series products. Because of the advantages of raw materials, production technology, process procedure, etc, stone paper wallpaper products is close to zero benzene, zero formaldehyde. Products do not contain harmful substances such as heavy metals, no smell, moistureproof, flame retardant and antibacteria. Upon health and environmental protection, it has made significant breakthrough! At the same time, due to the huge cost advantage of raw materials and the promotion of the new "one-stop sales service center" direct sales model, the price of environment-friendly wall paper is 20% to 50% lower than the price of similar products in the market

The third category: environmental protection stone paper series products. Mainly used to replace some traditional culture paper, packaging paper and special paper products; This kind of product changes the traditional papermaking technology. It does not use wood pulp, does not need to cut down trees, does not discharge strong acid and alkali and other chemicals, and does not discharge wastewater.

4. Significance:

The contribution of stone paper to the environment: stone paper is made of a large amount of inorganic mineral powder completely dissolved in a small amount of non-toxic resin. If the recycled paper is sent to the incinerator for incineration, a small amount of non-toxic and harmless resin will not produce black smoke or gas after incineration, and the remaining inorganic mineral powder can also return to the earth, back to nature.

5. Comparison:

New stone paper without wood pulp consider about the environmental cost, raw material, machining, market acceptance, future-oriented, and many other factors, and now it is unable to fully replace the traditional paper market, but the stone paper printing quality is similar to conventional paper, and has the physical properties of synthetic paper. The following will be the differences among wood pulp paper, synthetic paper and scode paper.

Recyclable: stone paper products can be recycled as plastic products, collected and crushed, extruded into PE plastic processed products, which can produce colored plastic bags, flowerpots, plastic buckets. The stone paper is sent to the incinerator for burning when it is used as garbage treatment, because it contains a large amount of stone powder and a small amount of non-toxic resin, only non-toxic resin can be burned. When the resin is combusted, the stone powder will powder and promote the contact between resin and air, helping resin completely burned, so in the combustion stone paper will not produce black smoke and toxic waste gas, meanwhile carbon dioxide emission is reduced, which can slow down the global warming. When stone paper is abandoned outside after use, and it will automatically be brittle into a broken eggshell state after about six months of exposure to the sun, and then it will return to nature (paper placed indoors will not be damaged without ultraviolet rays, and resin will not be brittle).

Protection of water resources and energy saving: stone paper represents a strong meaning of environmental consciousness. During the production of the stone paper products, the product completely needn't to be washed with water, and also do not need strong acid, alkali and bleach, so there is no issues about how to deal with wastewater discharge, the river pollution, the sea water pollution, and energy consumption for producing stone paper was lower than the consumption of traditional wood pulp paper. And it helps to improve the problems such as global warming caused by carbon dioxide .

(This is the first generation of Gwell Stone paper machinery , coating)

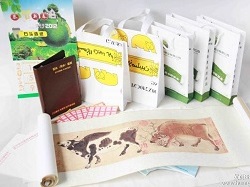

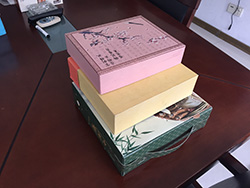

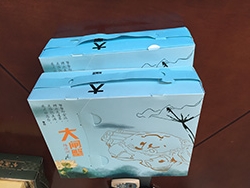

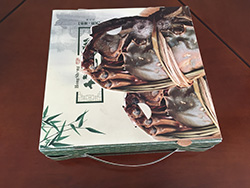

Application of the products from stone paper (PE + calcium carbonate) unidirectional stretch extrusion production line: the product application field is extremely wide. It can be used in disposable consumer goods, such as garbage bags, shopping bags, food bags, dense bags, lunch boxes, foot gloves, table cloth, raincoat, dust cover, etc. It can also be used in cultural paper, such as printing paper, writing paper, advertising decoration paper, daolin paper, coated paper, film paper, picture paper, poster paper, typist paper, mail cover paper, cigarette paper, gracing paper, newsprint, etc. Besides, it can be used in building materials decoration, such as decorative wallpaper; Also it can be used in industrial packaging and other fields, such as fertilizer bags, cement bags, rice flour bags, clothing bags, all kinds of handbags, cartons and so on; It can also be used in special paper, such as field paper, underwater paper, mine paper, military paper and so on. It can be said that the application field is very wide, and with the stone paper technology continues to mature and upgrade, the application field will be even larger. The cost of stone paper products is 20%-30% lower than that of alternative products. With extremely strong competitiveness, and the market prospect is very good. Now, stone paper has been widely used in wallpaper, book printing, food packaging, handbags, maps, posters, cards, with environmental degradation, oil proof, waterproof, mildew proof, insect resistance, tear resistance and other good performance.

Stone paper cutting base paper:

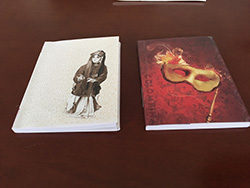

Printing paper, sample book and coated paper:

Printed book:

wallpaper:

Cards, labels, Bookmarks:

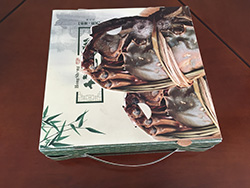

Carton and carton packaging:

Waterproof and breathable carton packaging:

Handbag, paper bag, packing bag:

Stone paper is divided into PP and PE, according to the usage of paper, selected materials and paper methods. Gwell offers complete solutions and turnkey projects. Stone paper/synthetic paper production line includes: material processing (granulation), salivation drawing (paper), coating (paper surface treatment) three parts. We provide a complete set of solutions such as factory layout planning, technical training for stone paper production staff, complete equipment production line, stone paper production process, and formula for each link of stone paper production. We have provided many sets of stone paper and turnkey project at home and abroad, and it have been widely recognized by customers.

Processing methods are divided into: salivary stone paper/synthetic paper production line; Unidirectional stretch stone paper/synthetic paper production line; Bidirectional stretch stone paper/synthetic paper production line.

Stone Paper, Synthetic Paper(PE+Calcium Carbonate)Extrusion Line(Please consult the sales engineer for details)

| Type | GWS130 | GWS130 | GWS150 |

| Type of product | Cast | Uniaxial tension | Biaxial tension |

| Width of product | 810mm | 1400mm | 2800mm |

| Thickness of product | 0.2mm - 1.5mm | 0.1mm - 0.5mm | 0.05mm - 0.5mm |

| Output | 5000 t/yr | 5000 t/yr | 8000 t/yr |