PP/PS sheet extrusion production line is common for single-extruder single-layer sheet production line and double-extruder co-extrusion three-layer sheet production line. There are also multi-extruder co-extrusion multi-layer production line, which can process 7-9 layers of composite sheet at most, such as high-barrier EVOH multi-layer co-extrusion production line. This type of extrusion line can process PP, PS, PE and other polyolefin materials.

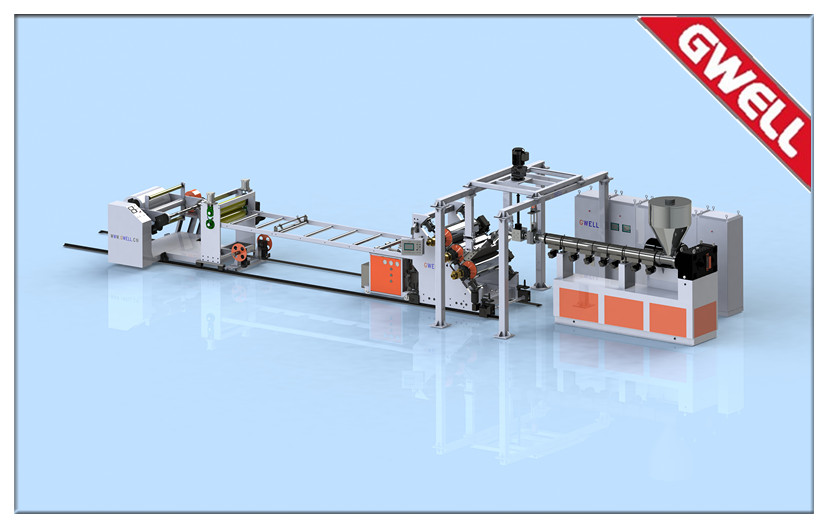

GWELL PP/PS sheet extrusion line:

Using multiple extruder co-extrusion technology to produce multi-layer co-extrusion composite PP and PS sheets, such as ABA, ABCBA, ABCDCBA and other multi-layer structures, which are widely used in thermoforming, printing, hardware packaging, electronic pallets, flocking, Food, clothing, tools, toys, stationery pieces, decorative pieces, etc.

* equipped with precise distributor, evenly layered, adjustable proportion of each layer, digital precise control.

* inclined horizontal structure, easy to operate and maintain.

* roller independent power, linear speed and extruder speed synchronous closed-loop control.

* the whole machine adopts PLC control to realize automatic control of parameter setting, data operation, feedback, alarm and other functions.

* Gwell independently wrote the electronic control operating system

Main applications of PP/PS sheet:

* PP/PS vacuum sheet

* PP/PS single layer sheet, PP/PS co-extruded two-color sheet, PP double-sided high-transparency sheet, etc. PP/PS sheet is mostly used in thermoforming packaging industry.

* PP stationery sheet

* PP transparent sheet, frosted sheet (coarse sand, fine sand), two-color sheet used in stationery packaging industry sheet.

* PP foam sheet, PP foam sheet has unique advantages, PP foam sheet with density of over 0.45g/m3 has a good bending resilience, not easy to deformation, so it has a broad prospect in the field of folders; PP foam sheet with density of 0.6g/m3 has good mechanical properties and has a very broad future in the field of automobile interior decoration. It can be processed into carpet support materials, shade board, sound insulation board, luggage rack, interior decoration, cover, box, etc. PP foam sheet with density of 0.3g/m3 has good flexibility and resilience, suitable for packaging, partition board and other fields.

| Type | PP/PS Single extruder production line | PP/PS Double extruder co-extrusion production line | PP/PS multi-extruder co-extrusion production line |

| single-layer sheet | double-layer sheet, three-layer sheet | even multi-layer sheet like five-layer, seven-layer and nine-layer. | |

| Extruder type | Optional single screw extruder or twin screw extruder | ||

| Product width | 600mm - 1220mm | ||

| Product thickness | 0.15mm - 3mm | ||

| Output | 200KG/H - 1000KG/H (There will be output differences among different machine models) | ||