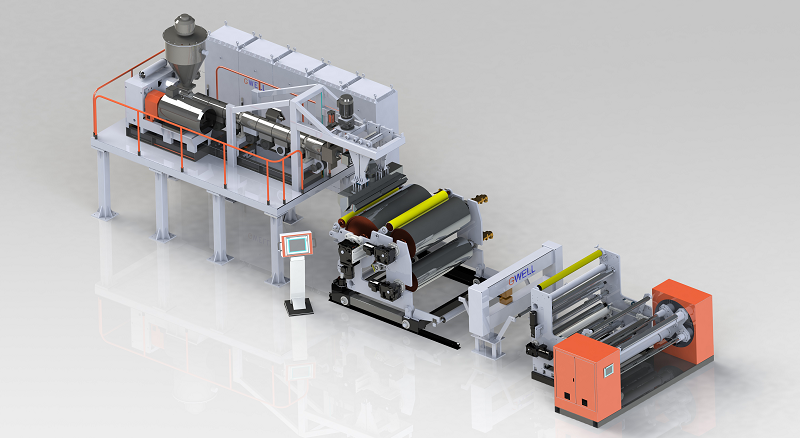

PVDF (Solar Backsheet) Film Extrusion Line

PVDF Solar Backsheet Film Extrusion Line,PVDF Film Production Machine

PVDF solar membrane USES: PVDF membrane is an alternative to "tedlar", used in the production line for solar plate composite materials, and also used in seawater desalination, sewage treatment, lithium battery diaphragm composite and outdoor building membrane engineering.

PVDF solar plate back film production line detailed description: PVDF film, technical name polyvinylidene fluoride. Our GWS75 production line can be used to produce PVDF film with thickness of 25-30 microns and width of 1250mm. The production line speed is 20m/min and the output can reach 120KG/H. GWS90 production line can be used to produce PVDF solar plate back film with thickness of 25-30 microns and width of 1250mm. The production line speed is 30m/min and the output can reach 180KG/H. GWS120 production line can be used to produce PVDF silicon wafer pickling thick plate with thickness of 1-10mm and width of 1250mm, and the output is about 350KG/H.

Common properties between PVF film and PVDF film: both for fluoride or fluorocarbon copolymer, they have a larger chemical bonding force and structure stability, therefore, it will not react with atmospheric pollution factors, even if the solvent with strong corrosion ability will not cause damage to it. So it can protects metal plate surface from rust, and protects decorative surface from fading or brittling; It will not be stimulated by uv then be changed in tissue structure. The sun will not accelerate its "aging"; It won't be changed in structure even if the work environment temperature keeps changing, and actually work environment allowing the change interval of temperature to reach by 180 ℃ (70 ~ + 110 ℃) can adapt to almost all areas of outdoor environment on the earth. Suzhou Gwell machinery Co., Ltd. has already provided many PVDF extrusion lines for many domestic companies. Film thickness uniformity, high thickness accuracy. The product has been fully verified by the market. PVDF membrane is used to replace dupont Tedlar (PVF) membrane in China, and the performance is almost the same. Welcome to visit and inspect!

PVDF film (polyvinylidene fluoride film) is a film made by salivation stretching. PVDF material has many advantages, such as: high wear resistance, high corrosion resistance, high aging resistance, good heat stability, flame retardant (low smoke), ultraviolet and nuclear radiation resistance, impact resistance, strong weather resistance, high mechanical strength and tenacity, mold resistance.

PVDF film (polyvinylidene fluoride film) is a film made by salivation stretching. PVDF material has many advantages, such as: high wear resistance, high corrosion resistance, high aging resistance, good heat stability, flame retardant (low smoke), ultraviolet and nuclear radiation resistance, impact resistance, strong weather resistance, high mechanical strength and tenacity, mold resistance.

PVDF film production line main USES:

1. PVDF solar plate back film production line: the film is used for solar plate back film to protect the battery, mainly for aging resistance and abrasion resistance;

2. PVDF outdoor decoration film production line: the film is used for the protection of glass, external walls, doors and Windows, outdoor billboards of outdoor buildings, mainly for aging resistance and abrasion resistance;

3. PVDF battery diaphragm production line: membrane is used for diaphragm applications in fuel cells and lithium ion polymer batteries;

4. PVDF filtration membrane production line: membrane filtration membrane is used for water purification treatment, divided into ultrafiltration membrane and microfiltration membrane. It is mainly used for sewage treatment, seawater desalination, and removal of macromolecules, bacteria, sediment, salt and other impurities.

5. PVDF piezoelectric film production line: PVDF piezoelectric film has the advantages of wide frequency response, large dynamic range, high sensitivity of power and electricity conversion, high mechanical property strength, easy matching of acoustic impedance, etc.

PVDF Solar Backsheet Film, Cast Film Extrusion Line

| Type | One single-screw extrude | Two single-screw extruders co-extrusion |

| Structure of product | Single layer | A;A/B;A/B/A |

| Width of product | 1250mm - 2200mm | 1250mm - 2200mm |

| Thickness of product | 0.02mm - 0.03mm | 0.02mm - 0.03mm |

| Output | 120KG/H - 180KG/H | 140KG/H - 200KG/H |

| Max linear speed | 30m/min | 30m/min |