PC、PMMA、GPPS、PET、MS Transparent Sheet Extrusion Line

Views:

Date:2018-04-13

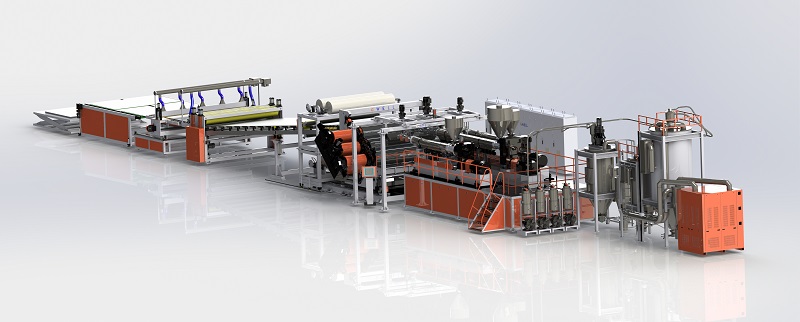

The production line of plastic transparent plate unit of Gwell Machinery Co., Ltd. fully absorbs and digests the world advanced extrusion technology of Europe and the United States. The main parts are world-class products (such as screw, barrel, roller, etc.), and the energy consumption, intelligence and automation indicators of the complete set of equipment are close to world-class products. This series of products has a number of invention and utility model patents, which is the first choice to replace imported first-class equipment, and has unparalleled cost performance advantages. The high-end transparent plate products are widely used in optical, home appliances, construction engineering, decoration, furniture, advertising, handicrafts and other industrial and civil industries. We have a first-class team of expert process engineers to help users debug and produce high-quality products.

1. Introduce of PC endurance board

PC endurance board has the characteristics of abrasion resistance and collision resistance, and it exceeds ordinary tempered glass in terms of strength. And it also has high toughness, can be bent to more than 90 degrees, and has good processing properties. Light texture and convenient transportation. The light transmittance is high, reaching 88%. A wide range of applications, such as: gardens, playgrounds, exotic decorations and gallery rest areas; interior and exterior decoration of commercial buildings, curtain walls of modern urban buildings; aviation transparent containers, motorcycle windshields, airplanes, trains, ships, automobiles, ships, submarines and glass military and police shields; the layout of telephone booths, advertising signs, and light box advertising exhibitions; isolation barriers between highways and urban viaducts.

2. Introduce of PC endurance board production machine

The PC endurance board production machine manufactured by GWELL has absorbed and digested the advanced extrusion technology of western countries. More than ten years of experience in manufacturing machines has prompted us to continuously improve the machine, improve the quality of the PC endurance board production machine and save energy, so that the PC endurance board produced has higher light transmittance, surface flatness and less use energy consumption to make more products.

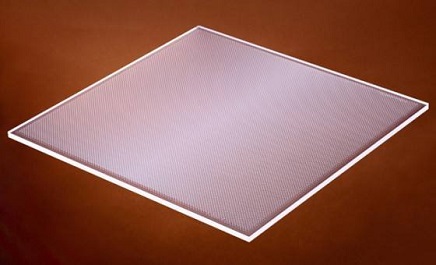

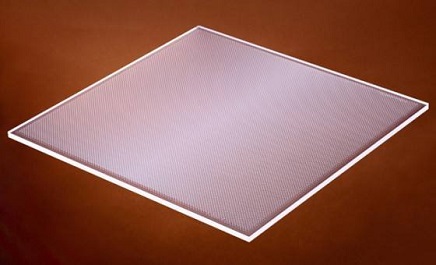

3. Introduce of PMMA light guide sheet

The main material of the light guide plate is an optical PMMA plate, which has high light transmittance, good weather resistance and good rigidity. The light transmittance is as high as 92%--93%. The heat distortion temperature is 100°C, and the maximum use temperature can reach 85°C. Because the light loss through the PMMA light guide plate is small, it is called optical glass.It can be used for the backlight of screen displays, and it can also be used for advertising light boxes.

4. Introduce of PMMA light guide plate production machine

The PMMA light guide plate production equipment manufactured by GWELL company uses GWELL's exclusive screw design and three-roller calender design to prevent defects such as crystal spots, black spots and whitening. With our auxiliary machinery, PMMA light guide plates can be produced more efficiently.

5. Introduce of PC and GPPS diffuser board

The light transmittance of this product is more than 80%, and the ordinary PC milk white board is only 20%; through the diffusion of the diffuser board, the entire surface of the board forms a uniform light-emitting surface without forming a dark area. No residual image will be formed on the screen, making the picture more realistic and achieving a crystal clear visual effect. It has few crystal points, high light transmission, high smoothness and good flatness. Also it has super impact resistance: 250 times of the strength of ordinary glass, 150 times more than tempered glass, and 30 times higher than that of tempered glass. Therefore, it will not break in the event of various accidents. Better protect your property and life safety. The lighter weight is convenient for the facilitates construction and reduces costs. UV coating on PC and GPPS boards can prevent ultraviolet rays from damaging indoor products and effectively extend the service life of PC boards. And combustion will not produce toxic gas. This product has good weather resistance and can adapt to harsh weather conditions of -40°C to 120°C, while still maintaining its performance.

6. PC/GPPS diffusion board production machine

This machine is very similar to the PC endurance board production equipment

7. PMMA (acrylic), GPPS, MS transparent plates:

PMMA (acrylic), GPPS, MS transparent plates are specially treated plexiglass, which is a replacement product of ordinary plexiglass. The light box made of plexiglass has good light transmission performance and pure color. Rich in color, beautiful and flat, taking into account both day and night effects, and long service life.Widely used in instrumentation, instrument parts, lamps, decoration, building materials, aircraft, auto parts, medical equipment, craft products, electrical insulating materials, specimens, signs and various lighting industry, culture, education, and daily necessities.

8. Introduce of PET (modified) transparent thick plate

high mechanical strength, rigidity and hardness. Good sliding performance and abrasion resistance, good electrical insulation. It has very good dimensional stability, weather resistance, and chemical resistance.

PET thick plates are processed from ordinary APET raw materials and special modified PET raw materials. Due to its superior cost performance, it can replace PC/PMMA/GPPS board in many occasions such as construction, decoration, and advertising. Our equipment can produce 5mm thick APET and PETG sheets.

9. Introduce of PET (modified) transparent thick plate production equipment

The PET thick plate extrusion line developed by GWELL Company is currently filling the lack of this kind of equipment in the market. PET thick plates have broad prospects in China. Compared with ordinary PET sheets, the maximum thickness can only reach 1.5mm, while the maximum thickness of PET thick plates can reach 5mm.

transparent sheet extrusion line Basic parameters (please consult sales engineer for details)| Type | Single screwGWS120 | Single screwGWS120 / GWS65 | Single screwGWS90 / 150 / 90 | Twin screwGWS75 |

| Raw materials | PC、PMMA、GPPS、PET、MS | PC、PMMA、GPPS、PET、MS | PC、PMMA、GPPS、PET、MS | APET、PETG

(modified) |

| Product structure | A | A;A/B;A/B/A | A;A/B;A/B/C | A |

| Product width | 600mm - 1500mm | 600mm - 2100mm | 1220mm - 5000mm | 600mm - 1500mm |

| Product thickness | 0.8mm - 15mm | 0.8mm - 15mm | 0.8mm - 15mm | 0.8mm - 15mm |

| output | 300KG/H - 350KG/H | 350KG/H - 450KG/H | 500KG/H - 750KG/H | 350KG/H - 450KG/H |