Melt blown fabric (melt blown non-woven fabric) is a product of composite non-woven fabric with high melt index PP (polypropylene) as raw material. It is the core material of mask. The diameter of spun fiber can reach 0.01 ~ 0.05 mm. It has many voids, fluffy structure, good anti wrinkle ability and unique capillary structure. The superfine fiber increases the number and surface area of fibers per unit area, so that the melt blown cloth has good filtration, shielding, heat insulation and oil absorption. Its main uses include air filtration, acid breaking liquid filtration, food hygiene filtration, industrial dust mask production, etc. in addition, it can also be used as medical and health products, industrial precision wiping cloth, thermal insulation material, oil absorption material, battery partition, imitation leather base cloth, etc. Since the outbreak of COVID-19 in the world, the SASAC of the State Council, in order to cope with the blowout of the core material of masks, requires relevant enterprises to speed up the construction of the production line, increase production as soon as possible, and expand the supply of melt blown nonwovens market, so as to provide protection for epidemic prevention and control.

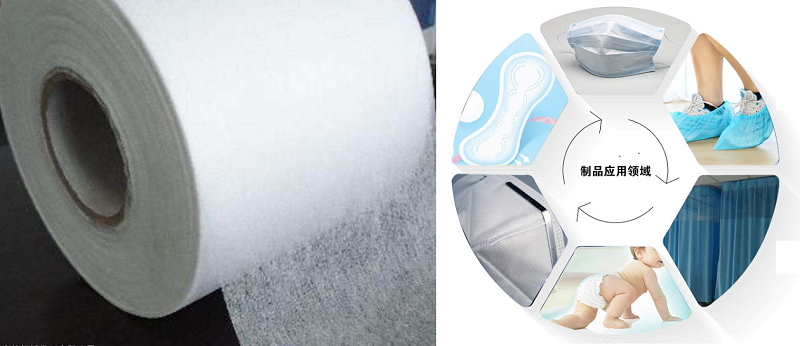

Common application fields of melt blown non-woven fabric:

1. Application in the field of air purification: it is used for air purifier, as a high-efficiency air filter element and for coarse and medium efficiency air filtration with large flow rate. It has the advantages of low resistance, high strength, excellent acid and alkali resistance, corrosion resistance, stable efficiency, long service life, low price and so on.

2. Application in the field of medical and health care: the dust-proof mouth made of melt blown cloth has small respiratory resistance, no suffocation, and the dust-proof efficiency is up to 99%. It is widely used in hospitals, food processing, mines and other workplaces that need dust and bacteria prevention. The anti-inflammatory and analgesic film made of the product after special treatment has good air permeability, non-toxic and side effects, and is easy to use, SMS products compounded with spunbonded cloth are widely used in the production of sanitary products such as surgical clothes and hats.

3. Liquid filter material and battery diaphragm: polypropylene melt blown cloth is used to filter acidic and alkaline liquids and oils. It has very excellent performance. It has been regarded as a good diaphragm material by the battery industry at home and abroad and has been widely used. It not only reduces the battery cost, simplifies the process, but also greatly reduces the weight and volume of the battery.

4. Oil absorbing materials and industrial wiping cloth: various oil absorbing materials made of polypropylene melt blown cloth can absorb 14-15 times of their own weight. They are widely used in environmental protection engineering and oil-water separation engineering. In addition, they can be used as clean materials for oil and dust in industrial production. These applications give full play to the characteristics of polypropylene and the adsorption of superfine fibers prepared by melt blown.

5. Thermal insulation material: the average diameter of melt blown fiber is 0.5-5 μ M, nonwovens are directly made by disorderly laying nets, so the melt blown fiber has large specific surface area and high porosity. This structure stores a large amount of air, which can effectively prevent heat loss. It is a filtering and thermal insulation material with excellent performance. It is widely used in the production of clothing and various thermal insulation materials. Such as leather jacket, ski shirt, cold proof clothing, cotton cloth, etc., it has the advantages of light weight, warmth preservation, no moisture absorption, good air permeability, no mildew and so on.

medical / civil mask materials - melt blown nonwovens product introduction:

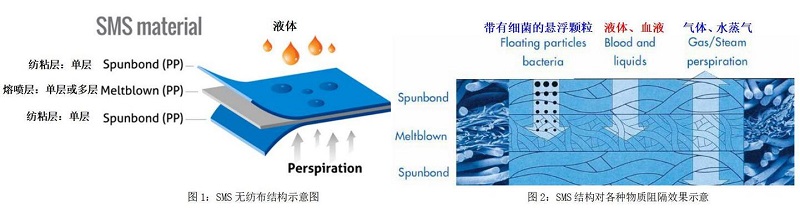

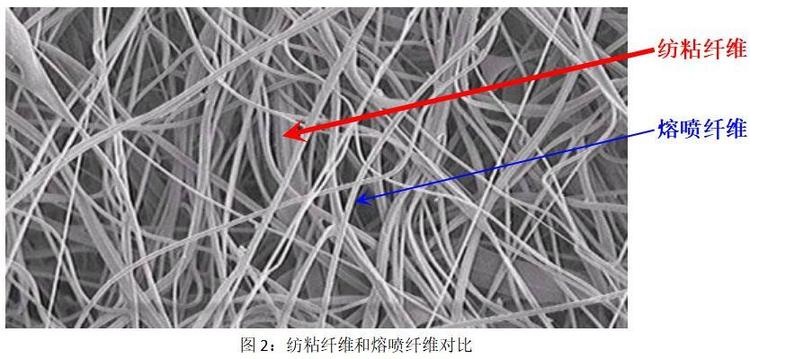

The raw materials of masks are all polypropylene (PP). Medical surgical masks are generally multi-layer structure, referred to as SMS structure, as shown in Figure 1 and Figure 2. S in the mask layer represents spunbonded fiber, with a relatively thick fiber diameter of about 20 microns (nm). The two layers of spunbonded fiber mainly support the whole non-woven fabric structure and have no significant impact on the barrier performance. The most important inside the mask is the barrier layer or melt blown layer (m). The fiber diameter of the melt blown layer is relatively thin, about 2 microns (m), which is only one tenth of the diameter of the spunbonded layer, which is very important to prevent bacteria and blood from entering the spunbonded layer.

Compare the shape of the fiber of the spun adhesive layer, the fiber of the melt blown layer and the hair. As shown below, about 1 / 3 of the hair diameter is close to the fiber of the spun adhesive layer, and about 1 / 30 of the hair diameter is close to the fiber diameter of the melt blown layer.

As mentioned above, the melt blown layer is thin and can prevent the entry of small particles such as bacteria. For a 5-layer mask made of polypropylene non-woven fabric smmms, from the perspective of material, the raw material of spunbonded layer s requires high strength and the raw material of melt blown layer m requires high fluidity.

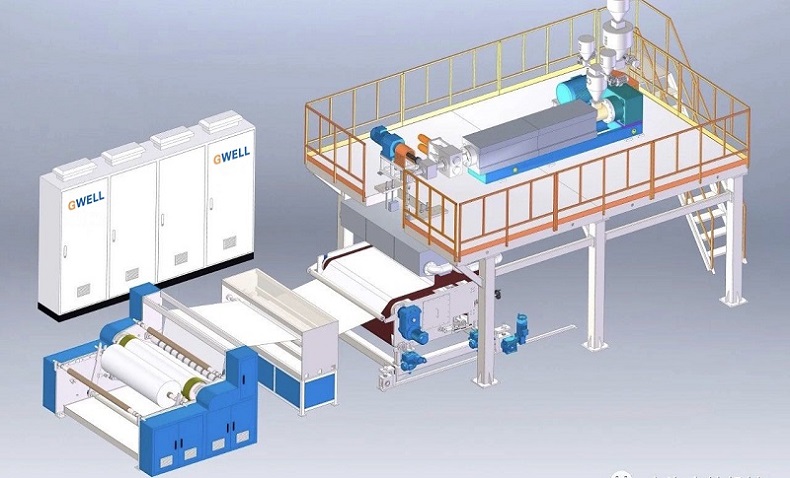

GWELL melt blown nonwoven production line:

With several years of industry experience, Gwell machinery timely responds to the needs of the country and the market and provides melt blown cloth production lines with various widths of 175mm-4200mm at a low price

Introduction to equipment advantages:

1. The gas equalizing spinning die is adopted, and the melt is evenly distributed.

2. The air pressure of the air nozzle is stable, the air flow on both sides is symmetrical, and the air flow in the width direction is uniform. The air gap width is easy to adjust.

3. The hot air flow heating device has good heating efficiency, excellent heat exchange efficiency and low energy consumption.

4. The receiving distance is adjustable, and the receiving form (flat screen receiving and drum receiving) can be easily replaced.

5. The fiber size and cloth surface are uniform.

6. The stationary polarization treatment makes the melt blown cloth have better filtering effect.

The performance parameters are as follows (please consult the sales engineer for details):

| Type | width | Gram weight | Line speed | size | capacity | delivery |

| GWS65 | 800mm | 15-150g/㎡ | 100m/min | 13mX5mX4m | 500KG/days | 10days |

| GWS90 | 1600mm | 15-150g/㎡ | 80m/min | 13mX7mX7m | 1400KG/days | 10days |

| GWS105 | 2400mm | 15-150g/㎡ | 80m/min | 15mX8mX7m | 1800KG/days | 90days |

| GWS120 | 3600mm | 15-150g/㎡ | 100m/min | 22mX9mX7m | 2000KG/days | 90days |

| GWS135 | 4200mm | 15-150g/㎡ | 80m/min | 24mX11mX7m | 3000KG/days | 100days |